Custom Injection Mold Solution

Prefect plastic product manufacturing starts with getting the right molds. And the right molds for manufacturing are those that can be automated, run fast and get the job done right every time.

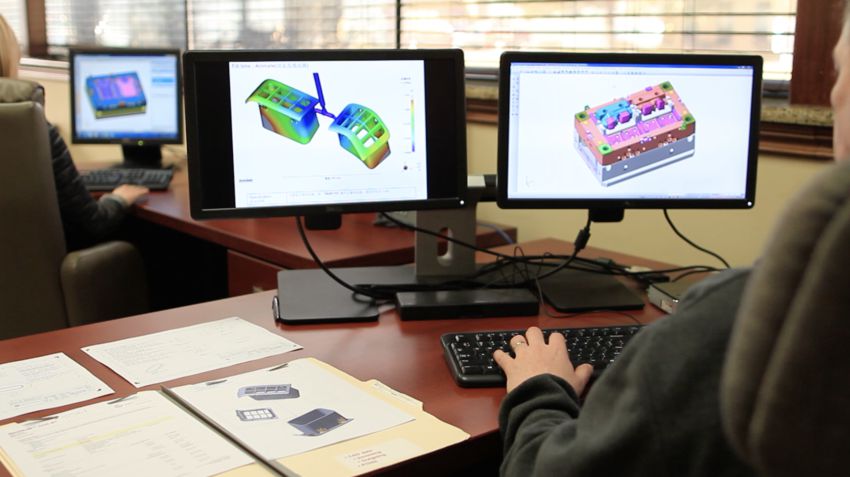

We will help you achieve shorter development cycles and reduced part cost. From the start of your product’s design phase, you’ll feel completely at ease with our friendly and professional team. We will analyze your drawings and 3D models and help identify potential problems in advance. By applying creativity and proactive ingenuity, we will advance your concept and ideas into a custom mold design that can be produced in the most cost-effective manner.

We will help you achieve shorter development cycles and reduced part cost. From the start of your product’s design phase, you’ll feel completely at ease with our friendly and professional team. We will analyze your drawings and 3D models and help identify potential problems in advance. By applying creativity and proactive ingenuity, we will advance your concept and ideas into a custom mold design that can be produced in the most cost-effective manner.

- DFM (Design for Manufacturability) Analysis

- DFA (Design for Assembly)

- Material Viscosity Curves

- Process Parameters & Simulation

- Melt Flow Simulation

- Shrink, warp and gas trap areas of concern

- Molecular Orientation

- Material Selection Assistance

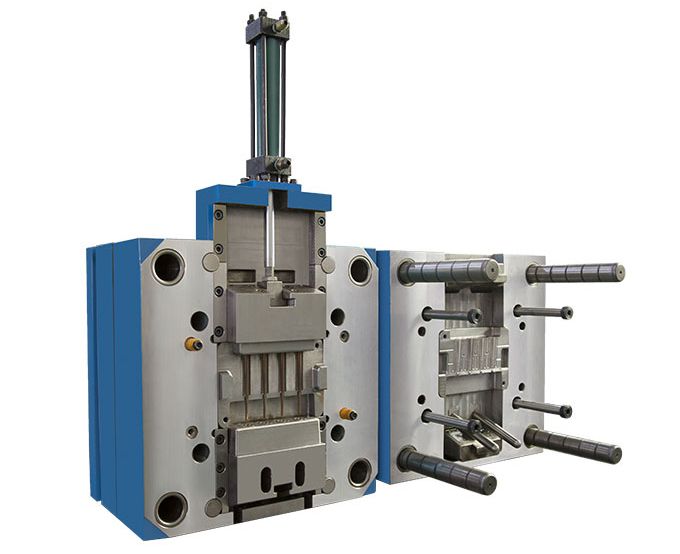

High Efficiency, Longevity, Performance Mold

By designing each tool with extreme accuracy and precision from the early stages there are minimal design changes after the initial prototype is created. The reduction of changes results in faster lead times and a reduced cost of manufacturing. We take careful measures and the required steps to ensure your tooling produces the highest-quality components while maximizing the life of the tool.

Our experts optimize mold designs prior to manufacturing to eliminate trial and error. This provides accuracy in validating before production (product/ design/ process) and helps you get your products to market faster. The Key asset value for quality tooling.

Our experts optimize mold designs prior to manufacturing to eliminate trial and error. This provides accuracy in validating before production (product/ design/ process) and helps you get your products to market faster. The Key asset value for quality tooling.

- Automatic Mold Maintenance Schedule

- Complex Slides and Side Actions

- Mold Modifications

- Hydraulic and Pneumatic Core Pulls

- Valve Gates, Sub-Gates, Cold Runners

- Sodick Precision Ram EDM & Wire EDM

- Mold Core Material : H13, Nak80, S136, etc.

- Mold Inspection and Management

- Effective Cooling Channels

- Preferred Gating (sizing, location and type)

- Scientific Venting

- Tight Tolerances

- High Cavitation Mold

- Two-color Mold

- Correctly Drafted Cores (fixed, floating, collapsible)

Innovative Mold Design

At Attractive Plastic, we always design for manufacture. This ensures ease of manufacture and aims to create a better product at a lower cost for our clients. Once we have a working design, we will go through the different tooling options available, helping you choose the correct mold or tool based upon the part’s expected use and a full cost/benefit analysis.

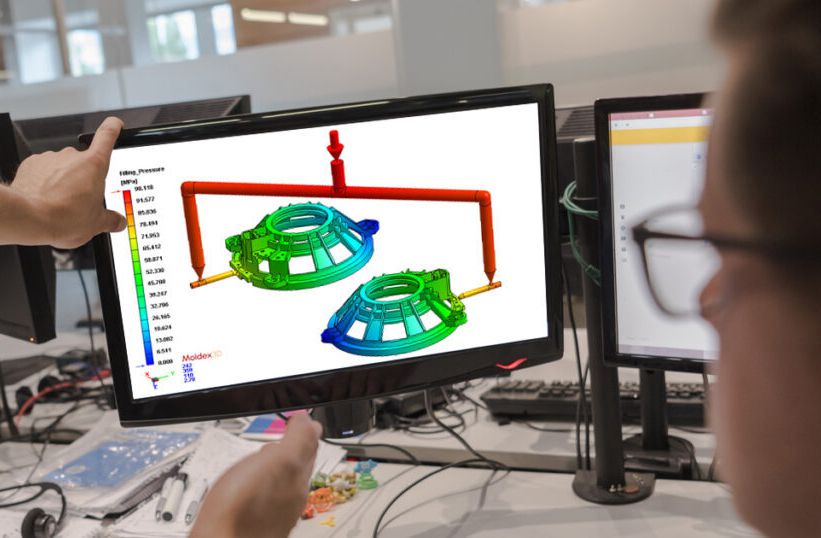

A lot of cosmetic imperfections occur because of the entry and flow of the resin into the mold. If there are issues with the injection gate or how the resin flows through the mold, it can lead to cosmetic and functional irregularities. These possible deformations in the surface finish of the product include; warping, shrinkage, bending, jetting, flow line and welding line.

Our extensive experience in injection moulding means that we have learnt to recognise when these types of deformations may occur and our design team is skilled in designing products with smooth and problem-free manufacturing in mind.

A lot of cosmetic imperfections occur because of the entry and flow of the resin into the mold. If there are issues with the injection gate or how the resin flows through the mold, it can lead to cosmetic and functional irregularities. These possible deformations in the surface finish of the product include; warping, shrinkage, bending, jetting, flow line and welding line.

Our extensive experience in injection moulding means that we have learnt to recognise when these types of deformations may occur and our design team is skilled in designing products with smooth and problem-free manufacturing in mind.

- Gate Type, Location Analysis

- Autodesk Moldflow Analysis Simulation

- Warpage Analysis

- Mold & Part Design Review

- Dedicated Project Engineer

- Finite Element Analysis (FEA)

- Processing Tolerance Confirm

- Structural Improvements

- Mold Insert Material Selection Recommendation

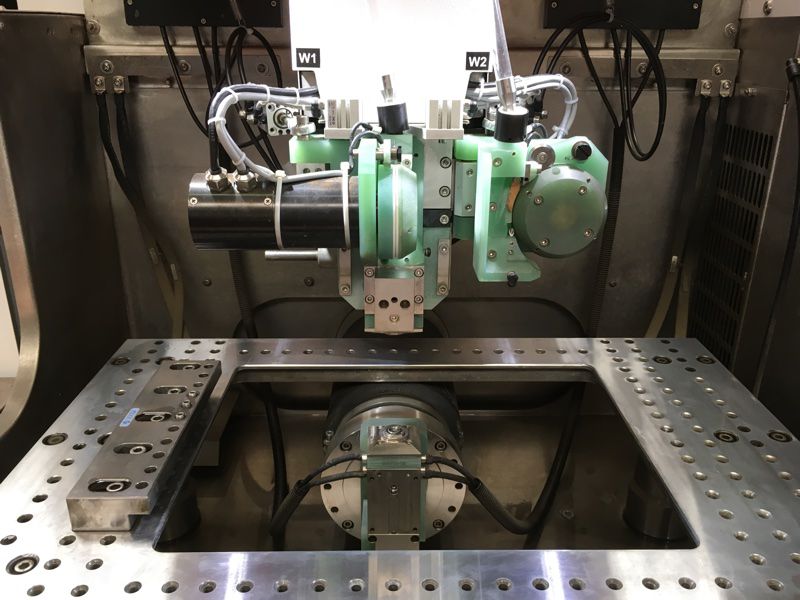

Superior & Precision Injection Mold Maching

As we know, perfect molds are related to professional mold design, high precision processing machines, rich experiences assembling moldworkers, and team management. We produce our mold on industry-leading CNC and EDM equipment with standard accuracies of +/- 0.005” on the mold, then hand bench for superior surface finish.

We are truly a full-service, in-house mold building resource. With 8 CNC Wire and Die Sink EDM machining centers available, along with 4 high precision 5-axis CNC Milling Machines—we have all the resources needed to efficiently, accurately and effectively manage multiple tool builds at a time. Our latest AG Charmilles Cut 2000S Wire EDM is Capable of precision as fine as .000040”, with finishes as fine as .80RA, while our Sodick 650L CNC Mill is capable of .000050” precision with surface finish as fine as 1nm.

If your project is demanding and requires extremely high precision and accuracy, Contact Us. Discover the benefit of working with a true full-service, engineering driven company.

We are truly a full-service, in-house mold building resource. With 8 CNC Wire and Die Sink EDM machining centers available, along with 4 high precision 5-axis CNC Milling Machines—we have all the resources needed to efficiently, accurately and effectively manage multiple tool builds at a time. Our latest AG Charmilles Cut 2000S Wire EDM is Capable of precision as fine as .000040”, with finishes as fine as .80RA, while our Sodick 650L CNC Mill is capable of .000050” precision with surface finish as fine as 1nm.

If your project is demanding and requires extremely high precision and accuracy, Contact Us. Discover the benefit of working with a true full-service, engineering driven company.

Control Mold Quality Key Point

Since 2000, Attractive Plastic has been a complete source for mold and injection molding. Our success is due to our ability to consistently provide customers with the highest quality parts, work within their budgets and completion dates, and ensure every customer need is met with outstanding service.

Our mold capabilities feature extensive, advanced wire EDM and CNC technology, coupled with a highly trained experienced mold worker. Our the Key asset value for quality mold. Following is some determine mold quality key factors:

Our mold capabilities feature extensive, advanced wire EDM and CNC technology, coupled with a highly trained experienced mold worker. Our the Key asset value for quality mold. Following is some determine mold quality key factors:

- Tooling Design Standards

- Balanced Runner Systems

- Cold & Hot Runners, Pin Valve Gate

- Scientific Venting System

- Even Cooling System

- Scientific Gate Type Location & Quantity

- Suitable Ejector System

- Coordinate Measuring Machine(CMM)

- Standard Surface SPI, VDI, Textrue Processing

- Technical Side Action (Lifters, Slides, Unscrewing Action, Collapsible Core)

- Mold Core Material Selection(Hardness and Some Special Request)

- Mold Inserts, Core, Slides, Lifters Tight Tolerance (Maintaining tolerances of +/- 25 microns)

Where Your Innovations Come to Life

The best and most creative innovations and products deserve the best toolmaking facilities, along with experts committed to seeing your project through completion. Our state-of-the-art toolrooms are thoroughly equipped and expertly staffed to support your injection molding projects throughout the entire program lifecycle. After design consultation and tool build, our team continues to stay engaged, offering rapid repairs, and modification, plus regularly scheduled maintenance. Our tooling solutions provide your organization with the lowest possible total cost of ownership for the lifetime of the mold.

Precision tooling requires design integrity, quality processes, advanced technology, and a zero-defects culture. From the earliest stages of part design, our highly skilled engineers team are engaged with your product team to ensure a seamless transition from prototype to production tooling. This attention to detail from the inception ensures faster development times, and projects that are optimized for the highest yields.

Precision tooling requires design integrity, quality processes, advanced technology, and a zero-defects culture. From the earliest stages of part design, our highly skilled engineers team are engaged with your product team to ensure a seamless transition from prototype to production tooling. This attention to detail from the inception ensures faster development times, and projects that are optimized for the highest yields.

- Part design assist with your design engineers

- Moldflow analysis mitigates risks

- Design for Manufacturing (DFM) helps to ensure mold and manufacturing success throughout the product lifecycle

- We offer mold making to address your quality, budget, and lead-time objectives

- Our facilities offer fully staffed and equipped toolrooms to perform scheduled maintenance to minimize downtime

- Our mold rooms support design modifications throughout the life of the mold

Why Choose Us as Your Mold Manufacturer

-

More than 20+ Years Experience

More than 20+ Years Experience

We are one of the best Chinese injection mold tooling suppliers with more than 20 years of experience. Our expertise is in the injection molding and mold design tooling industry. Especially in the automotive, medical,consumer goods, optical industry. -

Mold Material Selection

Mold Material Selection

Being experienced mould tool manufacturers, we understand the need for durable material during mold tooling. Our molds are made of hardened steel, which is selected through a screening process. The type of steel chosen falls under H13, NAK80, S136, etc. -

Professional Engineers

Professional Engineers

We have a team of professional engineers who have had more than a decade's worth of experience in the automotive, medical, consumer goods electronic industry. They know the demand of the industry and are ready to create plastic molding tools as per customer specifications. -

Design for Manufacturability(DFM)

Design for Manufacturability(DFM)

The design of the mold directly affects the quality of the finished product. Especially in the automotive, medical, optical industry. there are high requirements for the precision and quality of the molds. In the early stage of mold design, we focus on the reliability of the mold and make mold flow analysis on it. -

Reliable Mold Processing Equipment

Reliable Mold Processing Equipment

To ensure mold reliability, our molds are made of hardened steel, such as H13, Nak80, S136. Meanwhile, we have introduced foreign precision mold processing equipment. High precision processing equipment guarantee high precision during plastic mold manufacturing. Now, attractive plastic is equipped with precision manufacturing and measuring equipment such as mirror spark machines, high speed CNC and CMM. -

Cost Efficiency

Cost Efficiency

Our team has years of experience handling varied needs related to OEM plastic porducts. We have offered cost-efficient contract manufacturing solutions for years now.

Turnkey Precision Mold Manufacturing Solutions

At the heart of Attractive Plastic’s nearly 20 years in business is this: We build extremely high precision injection molds! One reason for our success is our laser focus on incredibly tight parting lines, shutoffs and alignment between slide faces. In most cases there’s practically no visible parting lines, witness lines or mismatch. Our high precision competency translates across all mold built at Attractive Plastic. This includes insert molding mold, overmolding molds, high temperature injection molding tooling, in-mold decoration mold, thin wall injection molding and micromolding mold with incredibly fast cycle times.

We're an engineering driven manufacturer of custom plastic injection molding products. We are experts in producing high precision complex plastic parts. These include electrical electronic shell, automotive under the hood components, magnet insert molding, overmolding parts, medical device compenents, optical appearance parts and any other tight tolerance injection molding part requiring a wide range of engineering grade thermoplastics.

We make mold and injection molding parts ranging from single cavity to multi-cavity high volume mass production mold. From innovative percision mold design and mold construction, through sampling, tool debug, approval and production, We provide our customers a complete turnkey plastic products solution. That solution comes with a Life of Program mold warranty for any production mold we design, make and remains at Attractive Plastic for production. Contact us discuss your project now.

We're an engineering driven manufacturer of custom plastic injection molding products. We are experts in producing high precision complex plastic parts. These include electrical electronic shell, automotive under the hood components, magnet insert molding, overmolding parts, medical device compenents, optical appearance parts and any other tight tolerance injection molding part requiring a wide range of engineering grade thermoplastics.

We make mold and injection molding parts ranging from single cavity to multi-cavity high volume mass production mold. From innovative percision mold design and mold construction, through sampling, tool debug, approval and production, We provide our customers a complete turnkey plastic products solution. That solution comes with a Life of Program mold warranty for any production mold we design, make and remains at Attractive Plastic for production. Contact us discuss your project now.