Design & Engineering Capabilities

We know for injection molding plastic products, the engineering and design development process is critical to achieving that success. We offer the full range of design, prototyping, and development services. We turn your concept into a manufacturable design, transfer it to initial production, then manage full-scale production.

At Attractive Plastic, we partner with our customers to create customized injection molding solutions. Design consultation with customers is critical in this process to optimize efficiency and apply cost-effective approaches to product development and solution implementation. Collaborative product design ensures adherence to industry best practices. Our engineering design services result in quality products and solutions that create lasting and mutually beneficial relationships and partnerships.

Good part designs and material selections help to:

At Attractive Plastic, we partner with our customers to create customized injection molding solutions. Design consultation with customers is critical in this process to optimize efficiency and apply cost-effective approaches to product development and solution implementation. Collaborative product design ensures adherence to industry best practices. Our engineering design services result in quality products and solutions that create lasting and mutually beneficial relationships and partnerships.

Good part designs and material selections help to:

- Reduce design changes after molds are built

- Reduce processing cycle times

- Reduce lead time

- Improve part quality

- Reduce mold cost

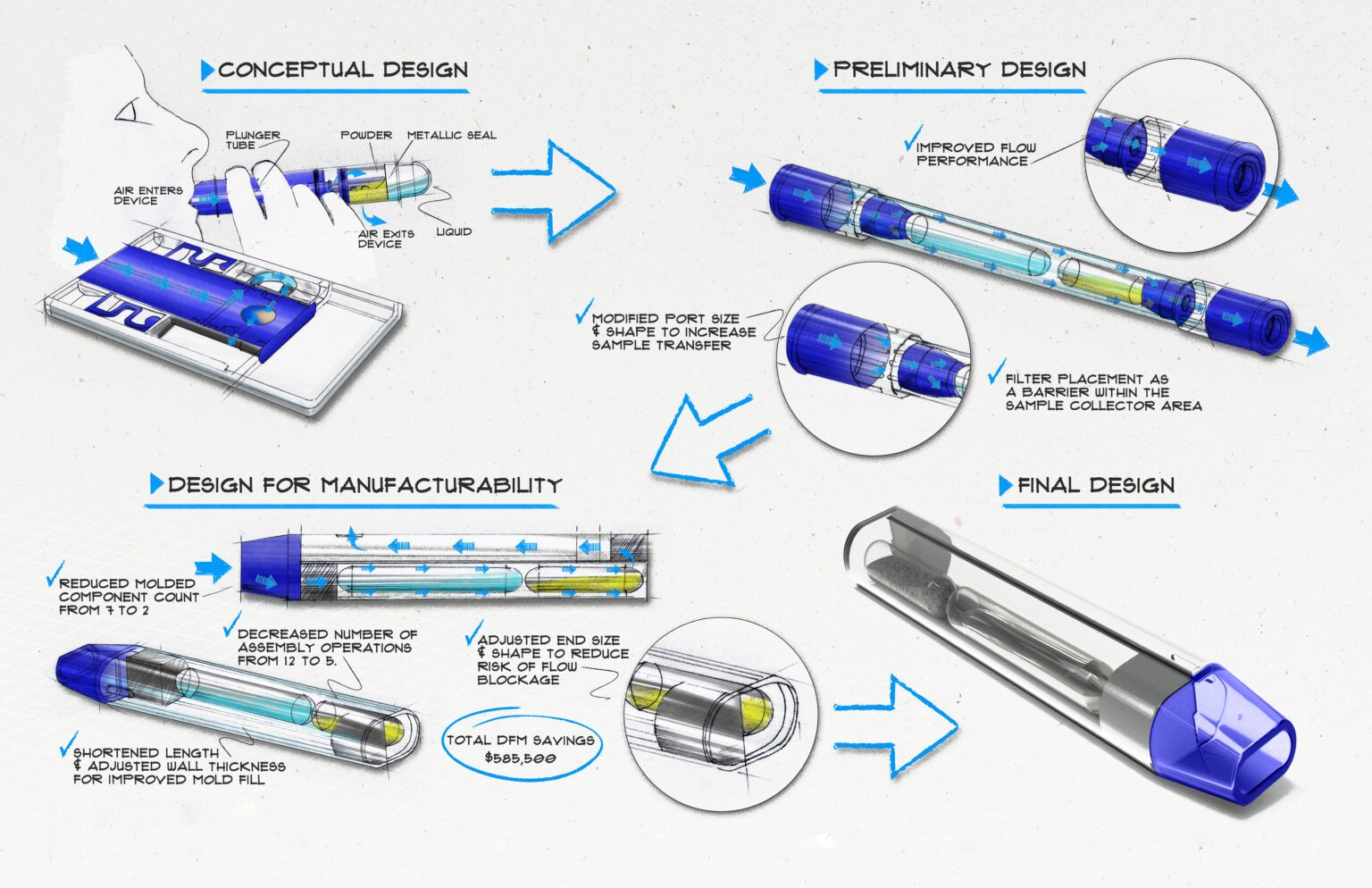

How Does Our Project Design Team Work?

- Concept Assessment - assess your goals and create the design brief - working out how we'll run the project to best deliver your goals

- Preliminary Design - using our knowledge and expertise to create the best product design for your needs

- Design For Manufacturability - keeping the manufacturing process front of mind at every stage

- 3D Printing And Rapid Prototyping - Eliminate potential design issues

Concept Assessment

Our team of product design experts help you assess the most efficient way to build your dream product. Whether what material is it or which industry products, we can sort out what you need and who you need to talk to.

During the Concept Assessment process, we seek to identify not only your needs but those of your customers and business stakeholders.

In order to take complete advantage of the value that injection molding can deliver, parts need to be designed with manufacturing in mind. We like to work with our clients on the front end of the process by reviewing their idea or designs and offering suggestions that will help make the project a success.

We always start a new project with a clear design brief. Providing you and the wider project team with clear direction and easy to read and comprehend project road map.

During the Concept Assessment process, we seek to identify not only your needs but those of your customers and business stakeholders.

In order to take complete advantage of the value that injection molding can deliver, parts need to be designed with manufacturing in mind. We like to work with our clients on the front end of the process by reviewing their idea or designs and offering suggestions that will help make the project a success.

We always start a new project with a clear design brief. Providing you and the wider project team with clear direction and easy to read and comprehend project road map.

Material Recommendation

Material selection is a critical part of high quality/low cost/fast production plastic injection molded parts and products. When it comes to selecting the right material, it takes experience, expertise and discussion to balance all of these factors prior to makiing a mold, as addressing specific needs early in the design process is key to avoiding costly changes later.

Physical design is only half the challenge when creating a part. Equally important is determining the best polymers or composite materials to be used to make your part based on its intended application. What temperature ranges and environments will the part function in? What type of forces or stresses will it be exposed to? Does it need to withstand sudden shocks or impacts? Is surface appearance important and will it need to be painted? These are just some of the considerations that go into selecting the right materials and additives to be used for any part.

We have the experience and are able to offer injection moulding in any type of thermoplastic polymer. The variety of different thermoplastics, from basic commodity polymers to advanced and specialised engineering grades, is wide. We have the expertise to advise on materials’ suitability and carry out necessary trials

Physical design is only half the challenge when creating a part. Equally important is determining the best polymers or composite materials to be used to make your part based on its intended application. What temperature ranges and environments will the part function in? What type of forces or stresses will it be exposed to? Does it need to withstand sudden shocks or impacts? Is surface appearance important and will it need to be painted? These are just some of the considerations that go into selecting the right materials and additives to be used for any part.

We have the experience and are able to offer injection moulding in any type of thermoplastic polymer. The variety of different thermoplastics, from basic commodity polymers to advanced and specialised engineering grades, is wide. We have the expertise to advise on materials’ suitability and carry out necessary trials

Preliminary Design

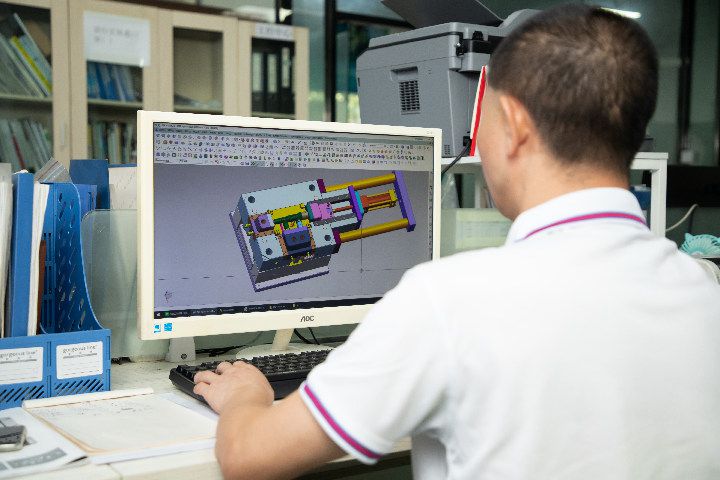

We’ve designed products for a wide range of industries, including automotive, medical, agricultural, electronic, electrical and consumer goods. Our product designers will consult with our engineers on materials and other variables that may impact the final result.

Our product design team have over 20 years of design and mold making experience and possess the depth of knowledge needed to create the best product design for your needs.

Our breadth of experience provides confidence that With a combination of speed, innovation, and utility, our product design team can help give you the highest quality solutions to bolster your business and achieve real results for your company.

We encourage early design consultation to optimize your design, save you money, and find ways to gain a competitive advantage for your product.

Our product design team have over 20 years of design and mold making experience and possess the depth of knowledge needed to create the best product design for your needs.

Our breadth of experience provides confidence that With a combination of speed, innovation, and utility, our product design team can help give you the highest quality solutions to bolster your business and achieve real results for your company.

We encourage early design consultation to optimize your design, save you money, and find ways to gain a competitive advantage for your product.

Design for Manufacturability(DFM)

We providing a comprehensive array of engineering expertise in plastics. By utilizing the latest technology for plastics flow simulation software, our Design For Manufacturability (DFM) process is hands down some of the best in the industry. With completing a full analysis of the products geometry, we are able to uncover significant opportunity for part design improvements that typically either reduce overall costs or increase the efficiency during the production process.

At every stage of the design phase, we consider how design choices impact manufacturing options. When designing a part, there are many variables, like size, shape, and thickness. Not only will the geometry of a part dictate how it will look, but also how it will be manufactured.

Quality products stem from good design. we collaborates with clients on sustainable product development and our team of experienced engineering staff members work with the latest technology to develop quality plastic parts.

Our Engineering Team has over 20+ years of experience in custom injection molding, and we protect all of our clients from costly mistakes that are identified during the early stages of development.

At every stage of the design phase, we consider how design choices impact manufacturing options. When designing a part, there are many variables, like size, shape, and thickness. Not only will the geometry of a part dictate how it will look, but also how it will be manufactured.

Quality products stem from good design. we collaborates with clients on sustainable product development and our team of experienced engineering staff members work with the latest technology to develop quality plastic parts.

Our Engineering Team has over 20+ years of experience in custom injection molding, and we protect all of our clients from costly mistakes that are identified during the early stages of development.

3D Printing and Rapid Prototyping

3D printing and rapid prototyping offers a proactive approach to processing problems or potential concerns that can be solved before full production manufacturing begins. It can provide valuable and cost-saving insights into potential manufacturability and quality issues. Our engineers can provide consultation to determine the proper raw materials for your plastic component’s specifications and requirements. it have many advantages:

- Product design review offers solutions prior to production

- Correct early design flaws

- Provides components quickly to visualize and analyze

- Develop quality inspection parameters prior to production

- Manufacture product fixtures prior to production

- Provides overall cost-savings through general part-analysis

- Preview potential problems

Custom plastic products design consideation

We offer free part design consultations to help our customers avoid the costly burden of needing to re-design or modify mold later in the product development cycle. Products design for injection molding can be made simple and save develop cost with the right knowledge or suggestion in the early stage. Some of the main topics for injection molding part design reviews include:

- Maintaining consistent wall thicknesses if available

- Proper draft angles and parting line

- Avoiding sharp corners

- Undercut, thread, etc. structure feasibility manufacturing

- Proper plastic material selection

- Advanced target cost planning

- Gate type, quantity and location

Our Strength for Design and Engineering

Attractive Plastic is known for offering the best product development services because we provide everything you will need to get your product to market under one roof. We do so with constant, clear communication and collaborative interactions to ensure we take your product to the next level whether that’s designing it specifically to your specs, or improving the design with approved modifications. Our product engineering and design team offers the following:

- Cross-functional expertise of engineering concentrations – By drawing upon the knowledge and experience of a team composed of engineers from various disciplines, we can design and develop a diverse range of products, approaching the process by weighing a wide array of ideas, tools, viewpoints, and strategies.

- Program management – We carefully oversees every stage of the development process, from initial design to large-volume manufacture of the finalized product. We ensure that all teams involved with the project are aligned with its goals and capable of coordinating with one another in a harmonious manner, where necessary.

- Advanced problem-solving techniques – Our wide-ranging expertise, which covers the design and manufacture of many kinds of products, gives us insights into anticipating and remediating production-related snafus that can interfere with the development process and disrupt production timelines.

- Knowledge across numerous industries – From automotive sector to the medical field, we have provided its full-service product design development and manufacturing expertise to organizations in many industries. We have the background required to manage virtually any kind of project successfully, no matter what kind of product needs to be created.